Terramac RT14R crawler carriers ensure a North Texas water supplier completes project on time

Each day the Tarrant Regional Water District (TRWD) delivers quality water to a large swath of north-central Texas. Based in Fort Worth, TRWD serves approximately 2 million residents in 11 counties across 5,800 square miles. Its coverage area stretches southeast from Fort Worth and encompasses Arlington, Mansfield, Corsicana and other cities.

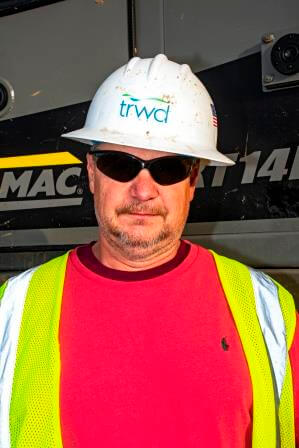

“We move raw water from the source to the taps,” stated Mike Weaver, Pipeline & Right-of-Way Supervisor. “One of the main ways we do that is by installing new and maintaining and replacing pipe as necessary.”

A recent project took a Pipeline Division crew to Navarro County to replace more than a dozen 20-foot joints of 90-inch concrete pipe near the Richland Chambers Reservoir. Approximately 40 people worked on the nearly month-long job, which involved removing old sections and installing new segments to correct a thrust and pressure issue.

“With pipe that large, you need a fairly sizeable trench in both depth and width and the sides sloped back properly to ensure safety,” said Weaver. “That was a challenge because the site was tight. We dug trenches with excavators, placed the dirt to the side and used dozers to push it away and into stockpiles for backfilling later.”

A wet winter with several inches of rain brought onerous conditions. For much of the project, aggregate bedding materials had to be stockpiled anywhere from 75 to 400 yards away from the open trenches. The distance between often had soft and muddy ground conditions.

“Dump trucks of any kind were really not an option,” said Weaver. “They would have gotten stuck, and then we would have had to pull them out. That ties up another piece of equipment, leads to more surface damage to repair and puts us behind. With a hard deadline, we needed a better solution.”

TRWD contacted local Terramac distributor Kirby-Smith Machinery to rent two rubber-track Terramac RT14R crawler carriers with 28,000 pounds of carrying capacity and ground pressure of only 8.3 PSI.

“We ran them on some really sloppy, nasty ground, and they floated right over it,” stated Weaver. “With the low-ground-pressure rubber tracks, the weight is evenly distributed, so you avoid making ruts and sinking into the soil. That helped us complete the project on time.”

Operator Joe McCune noted that another advantage of the 42,220-pound Terramac crawler carriers is the 360-degree rotating frame.

“Instead of pulling in, turning and backing up to dump with a truck, the Terramacs allow you to pull up, spin the cab and bed and then dump at any angle,” said McCune. “That’s very handy, especially in situations where there isn’t much space to work.”

Jordan Foote, a member of TRWD’s cathodic protection crew, was impressed as well.

“I have some experience running equipment, so within a few minutes of getting in the cab, I was able to work,” Foote said. “The joystick controls are great. Movement is controlled with the left joystick, while the spin and dump is handled with the right. Everything is laid out well, so even if you have never run a machine before, it would be easy to learn.”